The cannabis industry, while responsible for growing the legal cannabis we enjoy in many places around the world today, is known for not having the most environmentally friendly of carbon footprints. Unless you’ve been living under a rock, you realize there is a global call to end climate change — a call the cannabis industry can answer with more sustainable, environmentally conscious methods for cultivating cannabis.

A recent study published in the journal Nature Sustainability estimated the emissions associated with growing one ounce of cannabis indoors are about the same as burning seven to sixteen gallons of gasoline, depending on the conditions under which the cannabis is grown.

Because of the call for more sustainable practices in cannabis, cultivators are looking at ways to reduce their carbon footprint so their practices are as “green” as the cannabis they grow. One of the ways companies measure their sustainability goals is to look at and measure their carbon footprint. Simply put, a carbon footprint is the amount of greenhouse gases — primarily carbon dioxide — released into the atmosphere by a particular human activity.

Here are five strategies cannabis cultivators may consider for reducing their carbon footprint.

Adopt organic practices

While we’re not quite there yet for cannabis, hemp can be certified as organic under the U.S. Department of Agriculture National Organic Program. To be certified, a company must prove the land used to grow the hemp has been managed without the use of synthetic fertilizers and pesticides for thirty-six months before the crop was harvested.

Hemp companies that are certified as organic rotate crops regularly, use organic fertilizers, and undergo minimal soil tilling to reduce their carbon footprint. Hemp cultivators can use their certified-organic hemp status as a selling point for conscious customers, while also using organic principles to cultivate cannabis.

Reduce lighting

Lights are the biggest energy user in a cannabis cultivation facility, hands down, with the energy costs for cooling the plants adding to the carbon footprint.

Many cultivators use high-intensity discharge (HID) or high-pressure sodium (HPS) lighting because it is more affordable, but switching to light-emitting diode (LED) lighting can be much more energy-efficient. LED lights not only use less electricity, but also also produce less heat, reducing the pressure on HVAC systems for cooling. While LED lights may be more of an investment up front, that investment will pay for itself over time with energy cost savings.

Another way to reduce lighting is to grow cannabis in a greenhouse rather than an indoor cultivation facility. It’s estimated that for every gram of cannabis produced, greenhouses consume 26 percent less power and release 42 percent fewer carbon emissions than indoor cultivation facilities.

Switch to bio agents

Pesticides are needed and have their place in some cannabis grows, but more consumers are preferring cannabis that is clean, pesticide-free, and free of contaminants. As more states move away from chemical pesticides, cultivators are using beneficial insects, bacteria, and fungi.

These bio-agents work to control pests, outbreaks, and potential future outbreaks but are a chemical-free way that won’t potentially harm your plant or consumers. This method of growing is a bit more complicated to get started, but once the right ecosystem is built within the grow you’ll see results start to show directly through plant health.

Consider vertical growing

More and more commercial cannabis growers are using vertical growing as a method to reduce cost and increase yield, especially when space is limited. Vertical growing involves producing plants hydroponically in vertically stacked layers or vertically inclined surfaces under LED lights.

When growing vertically, plants require a lot more attention and control points because of the many variables that affect a grow and the number of plants within a vertical grow, including moisture levels and air circulation.

Vertical growing offers a number of environmental benefits including increased yield per square foot, reduced emissions from facility and plant maintenance, and consistent crop amounts without compromising quality.

Buy reusable materials

Waste management in cannabis is key, and it all goes back to the fundamental principles of “reuse, reduce, and recycle.”.

Investing in quality materials for planting pots and grow trays is one easy way to reduce waste. Many cultivators rely on “cheap plastic,” which degrades, cracks, splits, and breaks over time while also potentially harming the cannabis that’s grown inside.

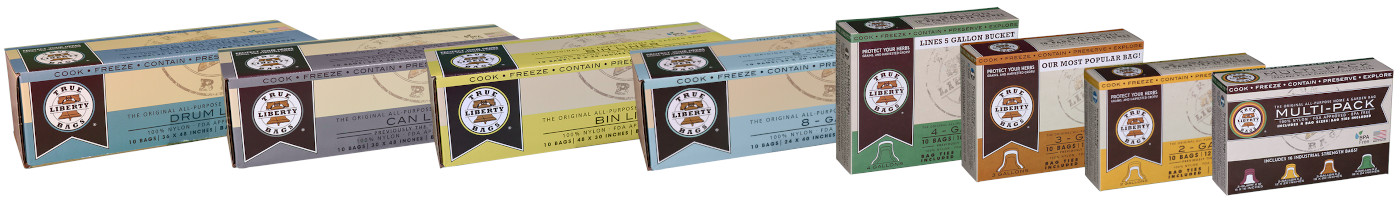

True Liberty®’s durable and versatile Pallet Container Liners helps protect storage containers from degrading, especially if they’re used to hold fertilizers or pesticides, and our Rolling Bench Table Liners help protect tables and trays.

We offer bags and liners of all sizes, sometimes known in cannabis as “turkey bags,” that are durable and designed for multiple uses, including to protect plants, freeze and cure, decarboxylate, irradiate, store, and transport precious buds. Our bags can be cleaned and sterilized so they’re reusable for multiple harvests. If new bags are preferred for every crop, then we encourage recycling.

Commit to reducing your carbon footprint

Every cannabis business can do its part to reduce their carbon footprint, no matter where they sit on the seed to sale spectrum. At True Liberty®, we operate at a net-zero carbon footprint through our CarbonFund.org contribution. In our operations, we use FSC-certified paper, recycled materials, and soy-based inks for packaging, and we donate to 1% For the Planet to ensure a healthy future.

For curing, trimming, storing, transporting, and the overall protection of the integrity of cannabis plants, we offer bags and liners of various sizes to integrate into your cannabis grow. Consider True Liberty® your partner in helping you build more sustainable practices into your cannabis cultivation as we build a more sustainable future together.

For more information, visit True Liberty® Bags.

Anne-Marie Fischer, M.Ed., has been a cannabis writer since 2016. She combines a background in community engagement, international development, and adult education to provide thoughtful, evidence-based content about cannabis for a variety of industry stakeholders.